ADVANTAGES

By utilizing this innovative technology, GlucosaGreen® offers a premium quality product with minimal impact on the environment.

Shellfish Glucosamine

Glucosamine products are traditionally derived from shellfish. This has many disadvantages including a destructive impact on the environment.

FAQ

Any questions about GlucosaGreen®? Click here to read our Frequently Asked Questions to know more about GlucosaGreen®.

Glucosagreen® – The Technology

GlucosaGreen® is the world’s first commercially available glucosamine produced by a revolutionary direct-fermentation process technology. This extremely efficient technology effectively addresses the many challenges inherent to chitin-derived shellfish production:

- Raw material availabilty

- Consumer concerns over allergens

- Environmental pollution caused by the process of extracting chitin from shellfish

The direct fermentation manufacturing technology that supports GlucosaGreen® is revolutionary because it dramatically addresses and solves so many of the challenges inherent in shellfish-derived, chitin production processes. The GlucosaGreen® process is a totally transparent, fully traceable, cost-effective, and sustainably produced glucosamine for brands and, ultimately, the consumer.

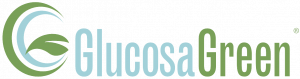

Instead of using shellfish as the raw material, GlucosaGreen®’s starting material is glucose. The glucose is derived from an easily available vegetable source; non-GMO corn.

From here, there is a fermentation process and the technology very efficiently transforms glucose into glucosamine – GlucosaGreen®!

GlucosaGreen®

Advantages of GlucosaGreen®

Vegan friendly

Shellfish free – allergen and kosher friendly

Able to provide full supply chain transparency and traceability

Safe: Safety and toxicity tested and verified, facility cGMP compliant

Animal friendly

Able to provide a sustainable, stable supply by using a food grade, non-GMO, abundant vegetable source as the starting raw material.

A vegetal (non-animal) product, and so has none of the impurity risks of animal products

A clean and efficient production process

Available in all glucosamine salt forms to meet individual needs

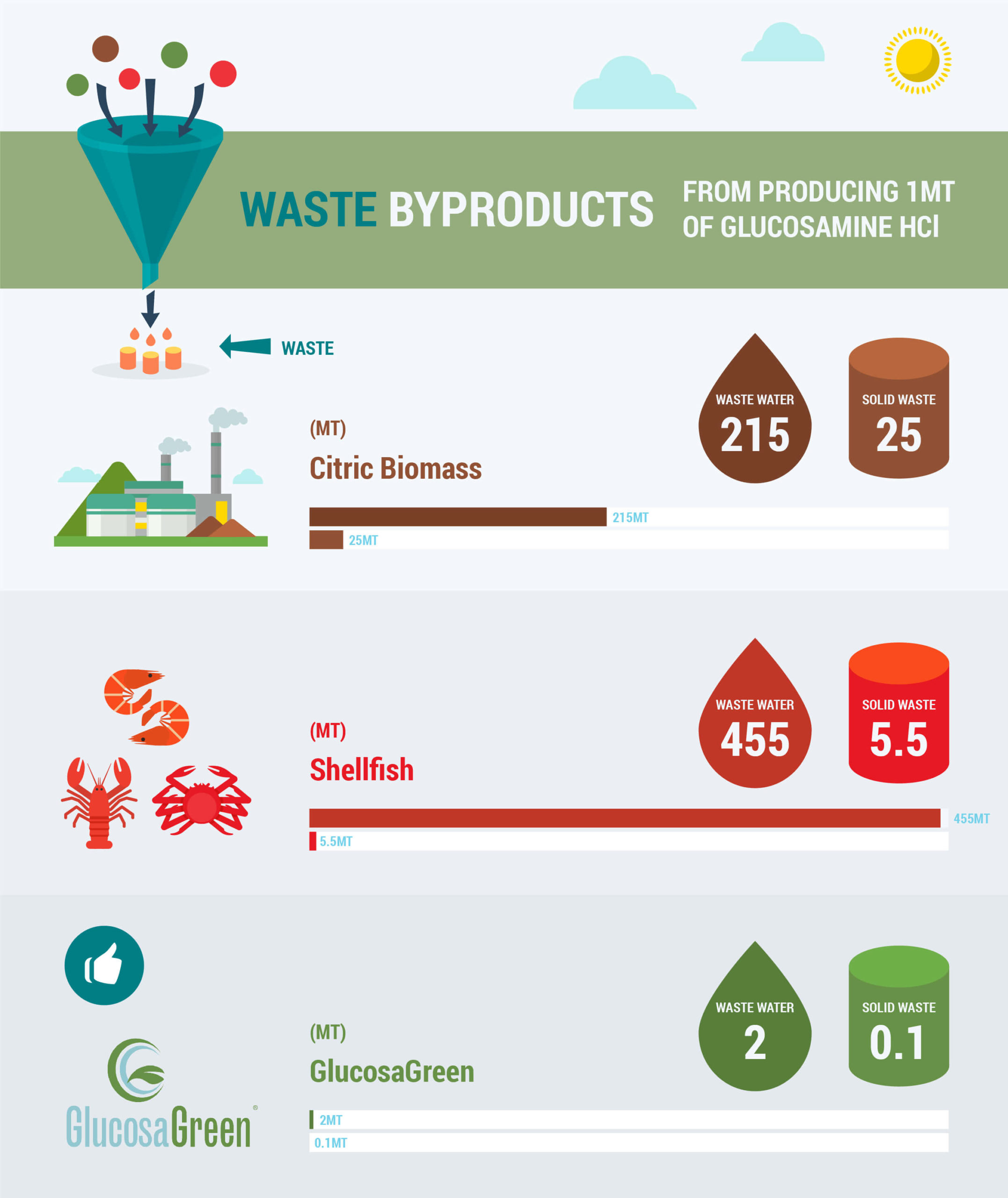

GlucosaGreen® only generates 1 metric ton of wastewater to produce 1 metric ton of glucosamine HCl, or approximately only 0.2% of the amount of wastewater generated in the process of making shellfish-derived glucosamine.

GlucosaGreen® is not dependent on a fragmented supply of crustacean shells or a limited quantity of citric acid biomass waste stream.

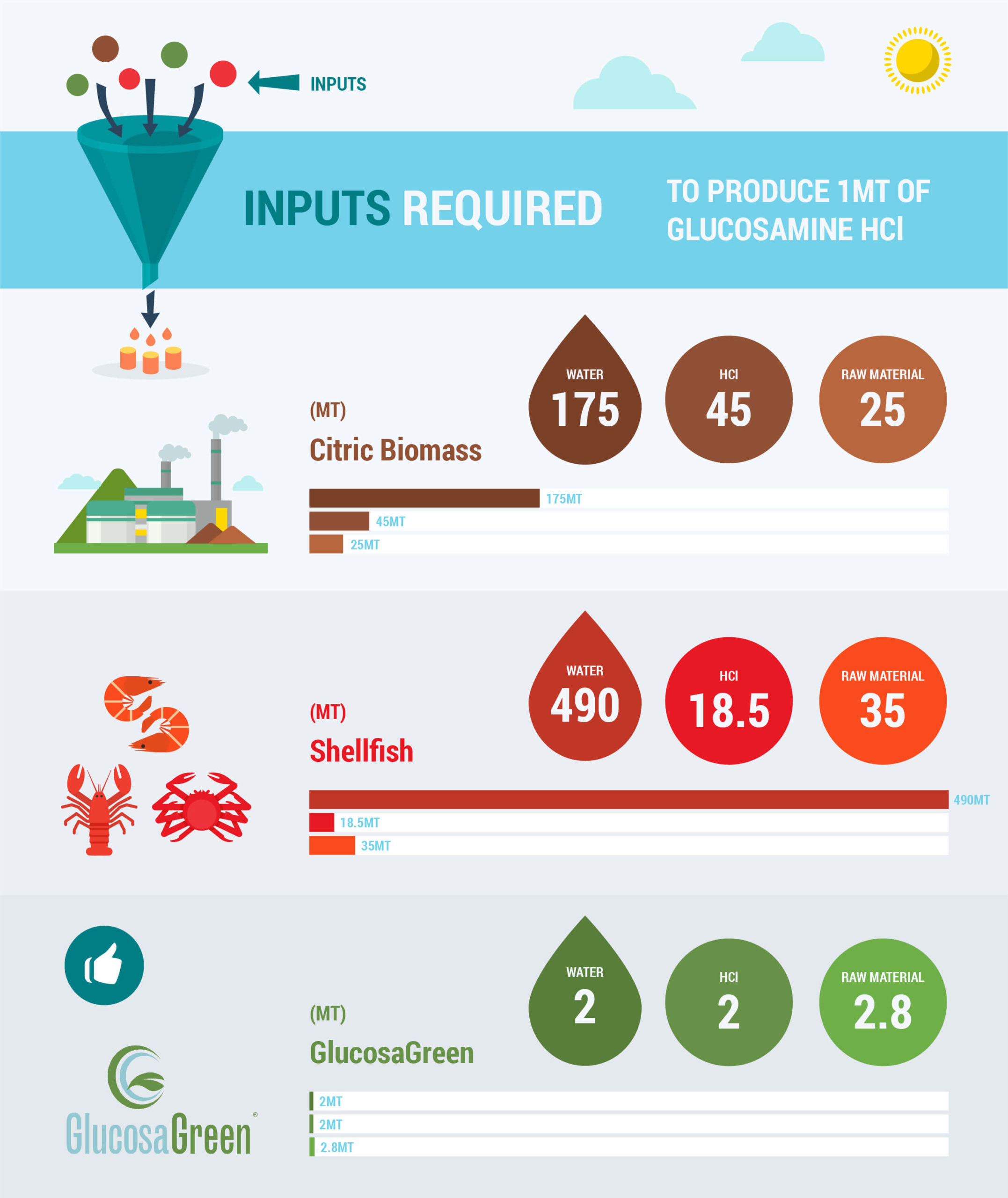

Some manufacturers use a citric biomass process for generating shellfish-free glucosamine. While this eliminates the need for shellfish as a raw material, it provides marginal improvement of water consumption and actually increases the solid waste generated.

GlucosaGreen® IS AVAILABLE IN MANY SALT FORMS TO MEET A RANGE OF REQUIREMENTS

Glucosamine Sulfate

Glucosamine Hydrochloride

N-Acetyl-D Glucosamine

GlucosaGreen® is also available in a selection of formats, including powders with an array of particle sizes, exclusive directly compressible granules for producing superior tablets, capsule grade for superior encapsulation, and other grades specifically for soft chews, a growing market for glucosamine for pets. We have the ability to create custom formulations as well as provide research, development, and pilot testing to address present and new challenges. Learn more.

GlucosaGreen®

SHELLFISH GLUCOSAMINE

SHELLFISH GLUCOSAMINE

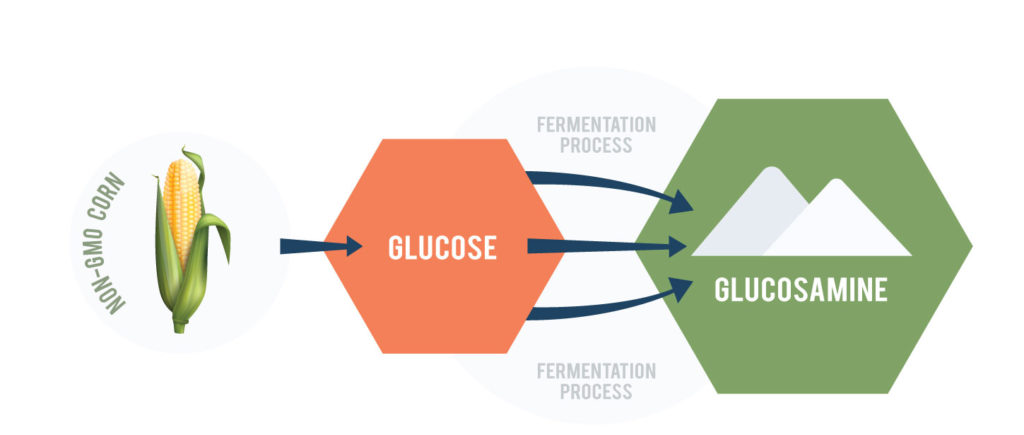

Much of the global supply of glucosamine is derived from shellfish. However, this has many disadvantages and deep-rooted deficiencies.

To produce 1MT of Glucosamine HCL, you need:

- 2,000kg of chitin (derived from shellfish)

- 5,000kg of NaOH (also known as sodium hydroxide or lye)

- 17,000kg of 30% HCl (hydrochloric acid)

This process generates 450 – 460 metric tons of wastewater with a PH of 5.5, COD of 8500mg/L. It is energy intensive, inefficient and is causing significant harm to our planet.

WHAT IS VEGETARIAN GLUCOSAMINE MADE FROM?

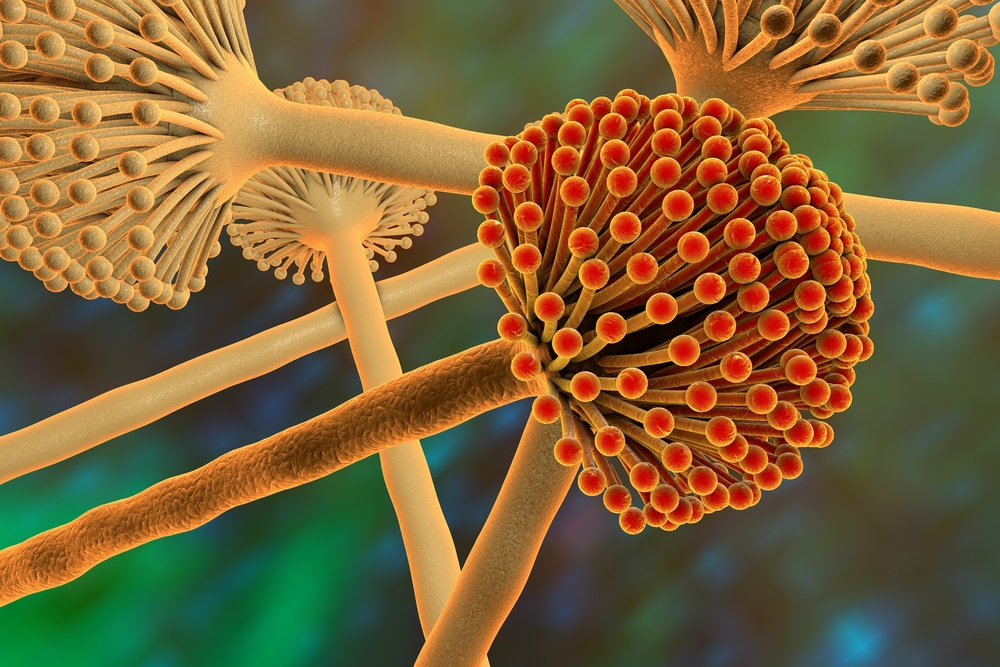

An older method used to produce vegan glucosamine is to derive it from the biomass of aspergillus niger. This is a fungus that has an outer shell rich in chitin similar to what is found in crustacean shells. This has traditionally been used for people who are allergic to shellfish or who follow a vegan or kosher diet. However, it also has significant deficiencies and comes at a high cost to the environment.

GlucosaGreen®

GlucosaGreen® VS TRADITIONAL GLUCOSAMINE

SAVES WATER

Shellfish glucosamine manufacturing requires 480 – 500 metric tons of clean water to make 1 metric ton of glucosamine HCI. GlucosaGreen® only requires 2 metric tons of clean water to produce the same amount of glucosamine. That’s 99.9% less water!

REDUCE SOLID WASTE

Producing 1 metric ton of traditional shellfish glucosamine requires 30 – 40 metric tons of shellfish shells, and creates 5 – 6 metric tons of solid waste requiring landfill. GlucosaGreen® is shellfish free and produces significantly less solid waste.

PRODUCES LESS HARMFUL GASES

The GlucosaGreen® manufacturing process requires significantly less hazardous chemicals, reducing the air pollution created in producing these chemicals that go into making shellfish-derived glucosamine.

PUT IT IN PERSPECTIVE

500 metric tons of water is enough to fill about one-fifth of an Olympic swimming pool!

REGULATORY COMPLIANCE AND QUALITY

Verified by laboratory testing to demonstrate bioequivalence to all forms of shellfish glucosamine

Manufactured to the highest cGMP standards

Non-GMO, shellfish-free and allergen-free

USP, JP and EP Compendial grades available

Available in all glucosamine salt forms

Available in ingredient and finished dosage form

GRAS affirmed

EU Novel food approval

ENVIRONMENTAL PROTECTION

FREQUENTLY ASKED QUESTIONS

About GlucosaGreen®

Vegetarian glucosamine is as effective as shellfish glucosamine. GlucosaGreen® has been tested and validated and provides an equivalent alternative in all forms. It is available as vegan, non-shellfish glucosamine sulfate as well as glucosamine hydrochloride in powder, tablet, and capsule grades.

Yes, glucosamine is generally recognized as a safe and well-tolerated dietary supplement. GlucosaGreen® has been validated to be bio-equivalent to all other forms of approved glucosamine, so it has the same favorable safety and tolarability profile as other dietary glucosamine.

Yes, GlucosaGreen® is vegetarian glucosamine made from non-GMO corn, and can potentially be used in an organic glucosamine supplement.

Yes, the raw material used to develop GlucosaGreen® is corn. Additionally, the manufacturing process does not utilize any animal products, and so is vegan friendly.

There are few natural forms of glucosamine found in food sources other then the shells of shellfish. However, as the shells of shrimp, crab and lobster are difficult to eat, it is left to glucosamine supplements to provide glucosamine ingredients.

To learn more, simply contact us.

Still have questions?